-

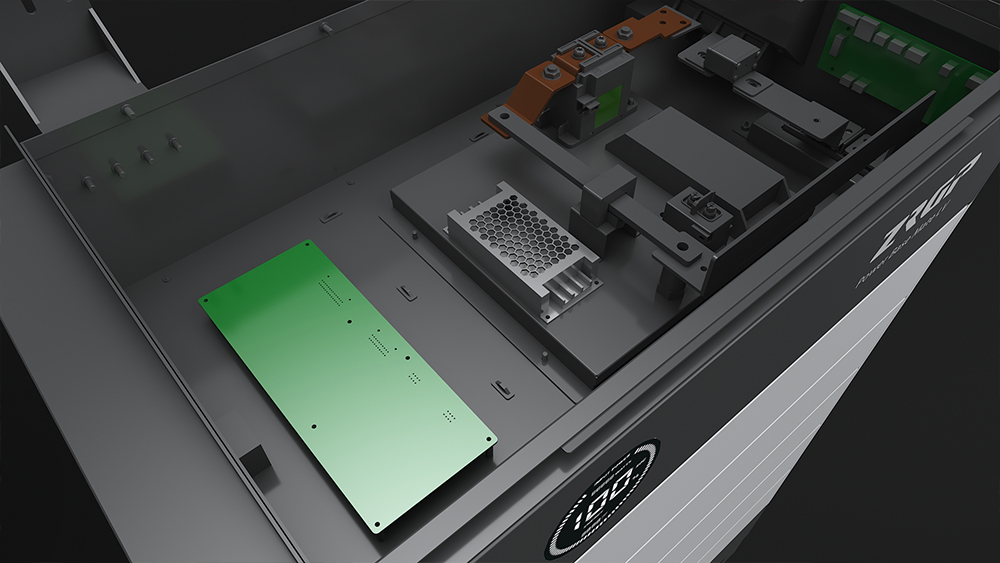

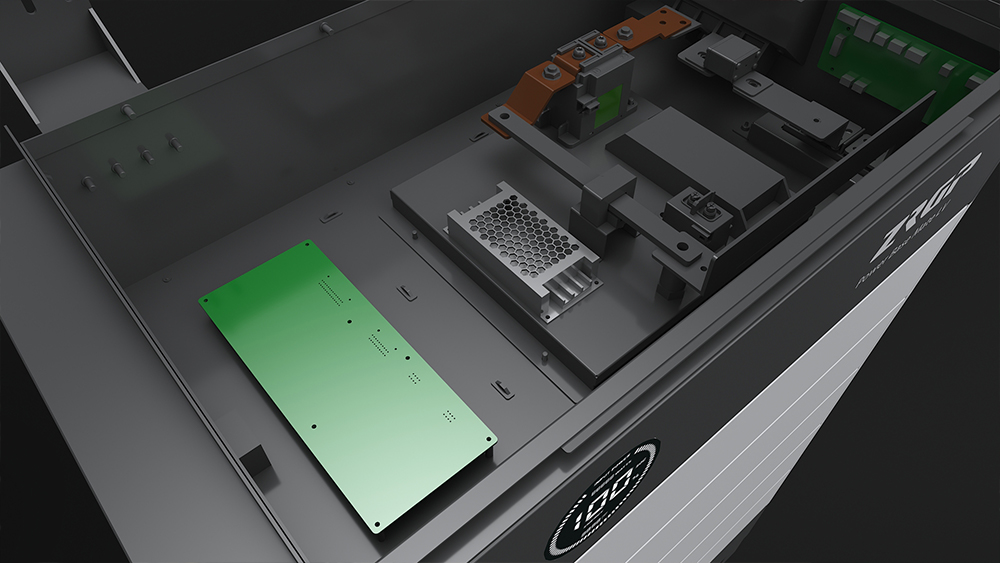

Comprehensive Testing and Inspection

Dec-Tue-2024 Excellence in Quality, Innovation, and EfficiencyZRGP’s testing system covers all aspects, from capacity testing to FQC sampling With over 20 test points verified via ATE systems, every product meets stringent quality and reliability standards before delivery

-

Multi-Level Protection:

Dec-Tue-2024 Hardware AdvantagesMulti-layer hardware protection and functional safety technologies ensure safe battery operation

-

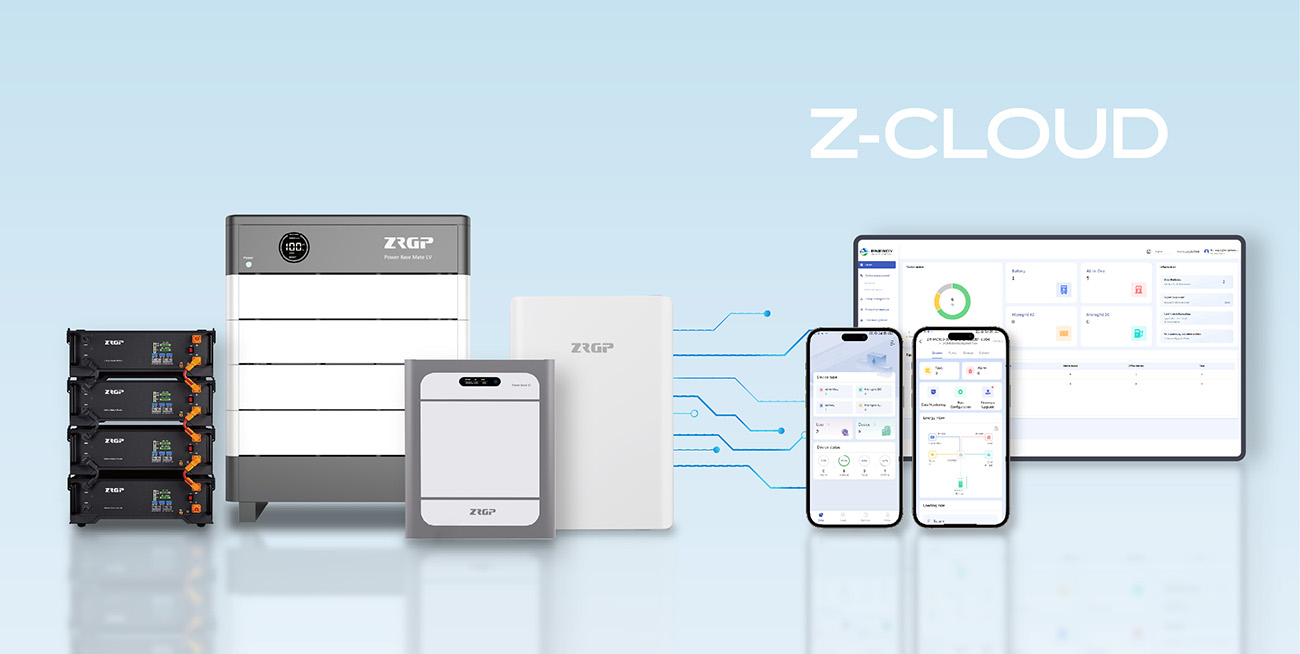

Security:

Dec-Tue-2024 EMS (Energy Management System)Implements robust access control and authentication mechanisms to ensure system and data security

-

Customizable Options:

Dec-Tue-2024 AdvantagesMultiple capacity and size choices are available to meet the diverse needs of different energy applications and environments

-

Strict Incoming Quality Control

Dec-Fri-2024 Excellence in Quality, Innovation, and EfficiencyZRGP’s 5th-floor inspection room ensures all raw materials meet high standards through rigorous sampling and advanced equipment This process guarantees quality from the very start, laying a strong foundation for reliable production

-

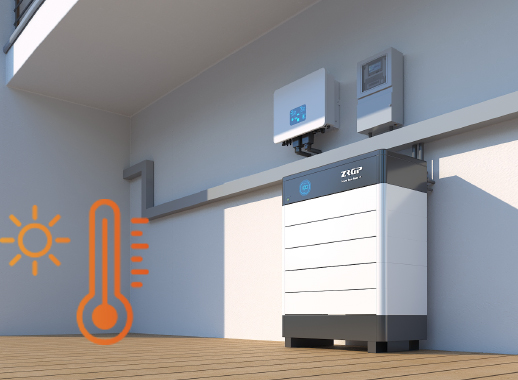

High-Temperature Protection

Dec-Fri-2024 TCS (Temperature Control System)Halts charging and discharging when battery temperature exceeds 50°C, enhancing safety and prolonging battery lifespan

-

Optimized Design:

Dec-Tue-2024 Software and Algorithm AdvantagesBig data and cloud platforms optimize battery pack design, improving performance and reliability

-

BMS Development

Dec-Tue-2024 Our Development HistoryZRGP started with Battery Management System (BMS) development, laying the foundation for future energy storage solutions

-

Data Integrity:

Dec-Tue-2024 Hardware AdvantagesReliable communication protocols and data storage technologies ensure data security and integrity

-

Efficiency:

Dec-Tue-2024 EMS (Energy Management System)Uses optimized algorithms and database technologies to enhance data processing speed and system responsiveness

-

Scalable Design:

Dec-Tue-2024 AdvantagesModular design enables rapid system expansion and easy upgrades, providing flexibility as energy demands grow

-

Factory Area

Dec-Fri-2024 ZRGP Global Influence and Production CapacityZRGP has a 21,000 square meter factory with advanced facilities, ensuring high-quality production and continuous innovation to meet growing market demands